Life Cycle Assessment Of A PET Single-Use Plastic Bottle

Project Description: Life Cycle Assessment of a PET Single-Use Plastic Bottle

Project Background:

The growing environmental concerns related to plastic pollution have intensified the need to understand the environmental impacts of single-use plastic products, particularly PET (Polyethylene Terephthalate) bottles. PET bottles are widely used in the beverage industry due to their lightweight, durability, and cost-effectiveness. However, the environmental footprint of these bottles, from production to disposal, presents significant challenges, especially given the low recycling rates and the accumulation of plastic waste in natural environments.

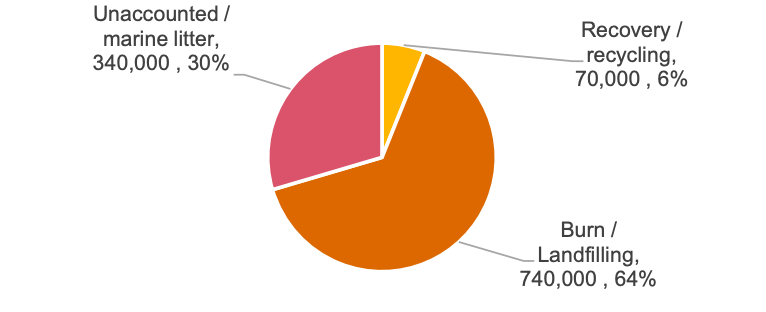

Plastic pollution is a critical issue in Nigeria due to inadequate waste management infrastructure. Lagos alone produces 8,400 metric tons of waste daily, with over 11% being plastics. The country's per capita plastic consumption has risen by 5.9% annually from 2007 to 2018, driven by increased plastic imports and domestic production. Nigeria imports 63% of its plastic resin, with only 28% produced locally. The plastic packaging sector, which has grown by 40% in the last five years, contributes significantly to the 1.15 million tons of plastic waste generated annually. Currently, only a small fraction of PET waste is properly managed, with the majority ending up in landfills, being incinerated, or contributing to marine litter.

Product Background:

The product under analysis is a typical PET single-use plastic bottle, commonly used for packaging drinking water. PET is a type of plastic known for its strong, lightweight, and recyclable properties. The standard life cycle of a PET bottle includes raw material extraction, manufacturing, transportation, consumer use, and end-of-life disposal.

Summarized Design Brief:

This project aims to conduct a comprehensive Life Cycle Assessment (LCA) of a PET single-use plastic bottle. The goal is to evaluate the environmental impacts associated with each stage of the bottle's life cycle, identify key hotspots where the greatest environmental impacts occur, and explore opportunities for improvement. The analysis will cover the entire life cycle, from raw material extraction to production, distribution, use, and end-of-life disposal. The findings will inform strategies to minimize the environmental footprint of PET bottles.

Intro to LCA

Traditional product design often prioritizes functionality and aesthetics while overlooking the environmental impacts across a product's life cycle. Life Cycle Analysis (LCA) addresses this by evaluating environmental impacts from raw material extraction to disposal. This report uses LCA to assess the environmental profile of PET (polyethylene terephthalate) water bottles, which are widely used for packaging beverages and other liquid products due to their effective barrier properties. LCA is a four-step process that measures emissions and environmental impacts at each stage of a product's life, providing a comprehensive understanding of its sustainability.

Goal and Scope Definition

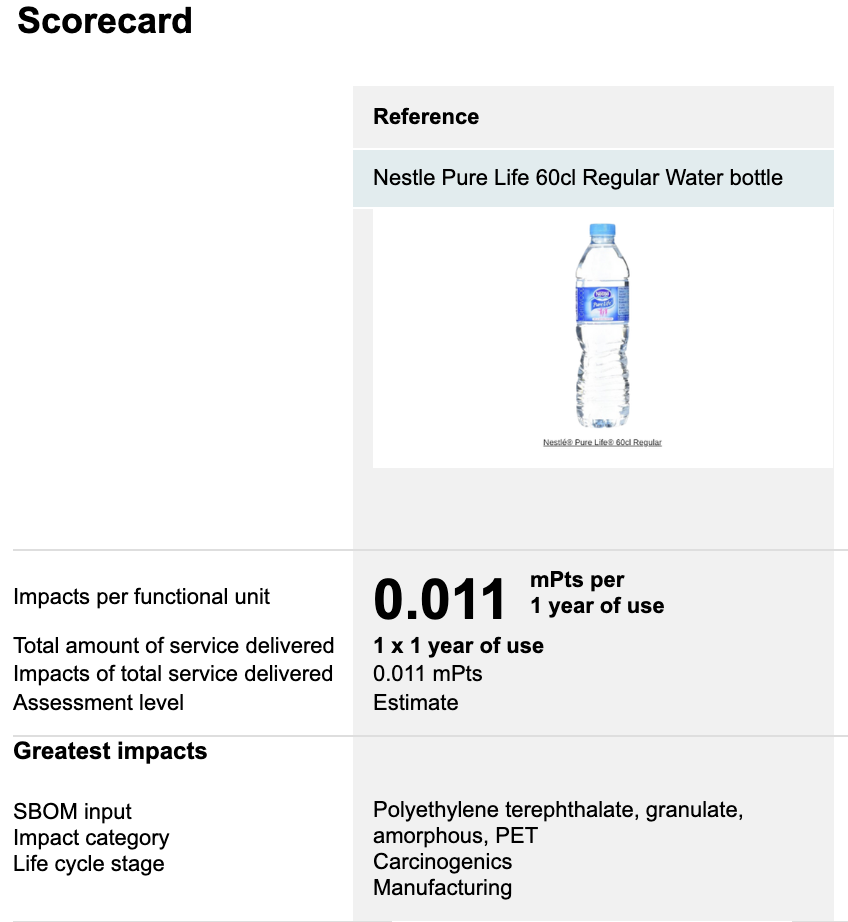

To identify the environmental hotspots of PET water bottles and inform design improvements. For the PET bottle, I have chosen the Nestle Pure Life 60cl Regular Water bottle

Intended Audience

The target audience for this LCA includes all individuals who drink water or use plastic bottles, as well as PET bottle manufacturers, particularly in Nigeria. The aim is to raise awareness about the most harmful processes associated with PET bottles and to encourage the development of more sustainable alternatives.

Scope of LCA

System Boundaries

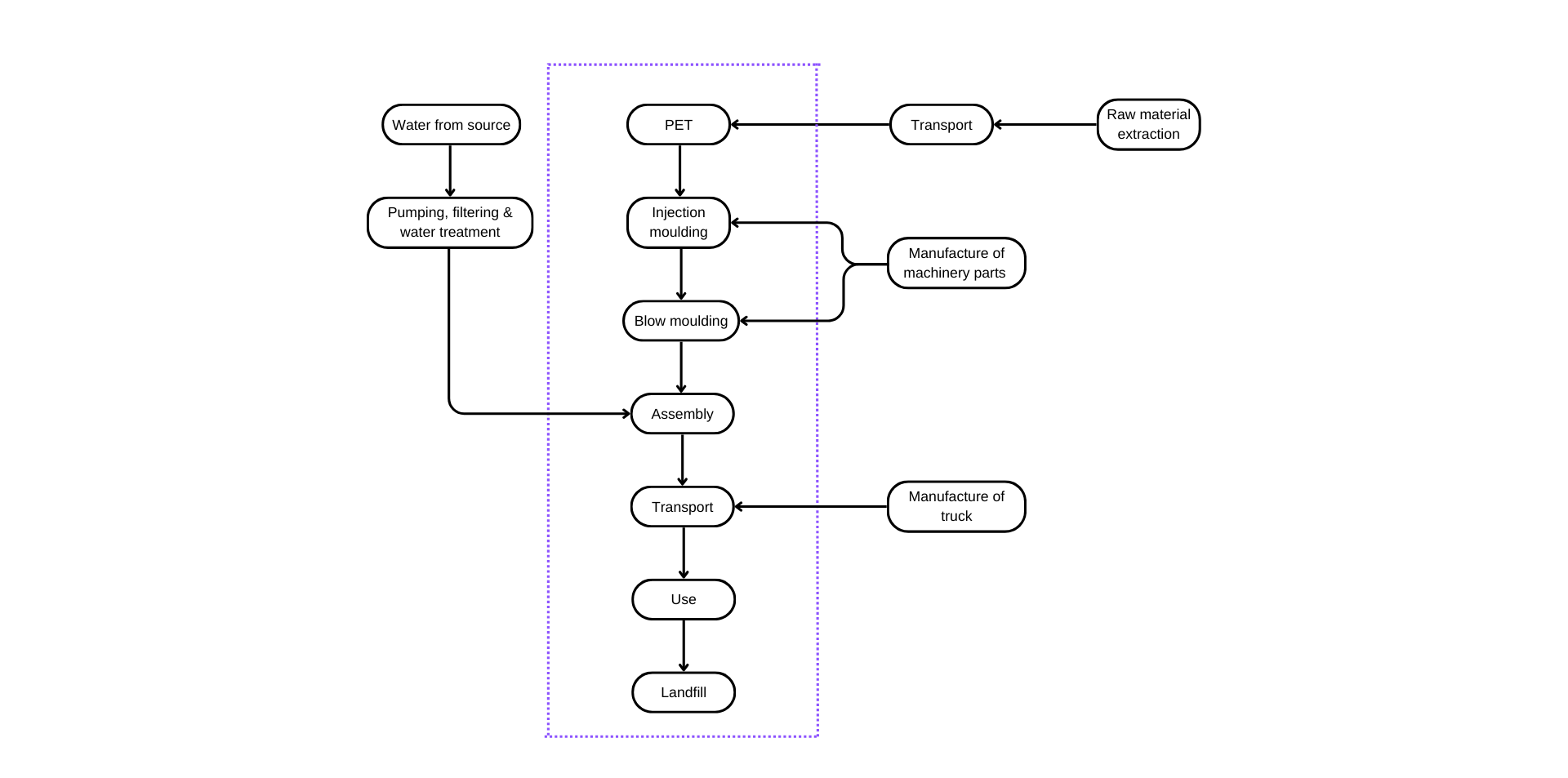

- Cradle-to-grave (includes raw material extraction, manufacturing, use, transportation, and end-of-life)

Functional Unit:

- 1 PET water bottle (60 cl). The amount of water carried during its entire lifespan

Boundary Exclusions:

- Packaging, heat, and energy use

Life Cycle Inventory (LCI)

LCA Flow Diagram

Data Collection Procedures

The data and information for the impact assessment and material inventory of PET bottles were based on estimated usage patterns, information from industry experts/government agencies, and scientific literature.

Key Assumptions

The assumptions of our LCA will be as follows:

- The entire PET water bottle is made only from PET

- The mode of transport is trucks

- We assume the duration of transporting the bottles as the average distance from the Nestle factory to Ikeja, Lagos, Nigeria.

- We assume the end-of-life method for the PET water bottle is Landfill

Overview:

Use: One-time use

Liter: 60 cl

Bottle Cap: 2.1 g

Bottle Body: 27.6 g

Label: 0.8 g

Manufactured: Nestlé Factory Agbara, Nigeria

Materials imported from: N/A

Transported to: Ikeja, Lagos

Disposal: Landfill

Manufacturing phase of PET bottles

The PET bottle considered in this study was assumed to be produced from 100% virgin PET resins which are petroleum-based materials. Also, the bottle weight analysed included the assumed weights of both the bottle cap (polypropylene), label (low-density polyethylene), and bottle body (Polyethylene Terephthalate). These assumptions are supported by previous research.

Transportation phase of PET bottle

Transportation of the bottle from the production plant was considered in this study. The bottle manufacturing plant (Nestlé Nigeria Plc) is located in Agbara, Ogun State. A distance of 50 km was estimated from the bottle factory to Ikeja, Lagos (Assumed location of the market) using google maps. The mode of transportation was an average truck.

Use phase of PET bottle

I excluded the use phase of PET bottle in this calculation

End-of-life phase of PET bottle

In modeling the disposal phase of the PET bottle, we assume the end-of-life method for the PET water bottle is Landfill

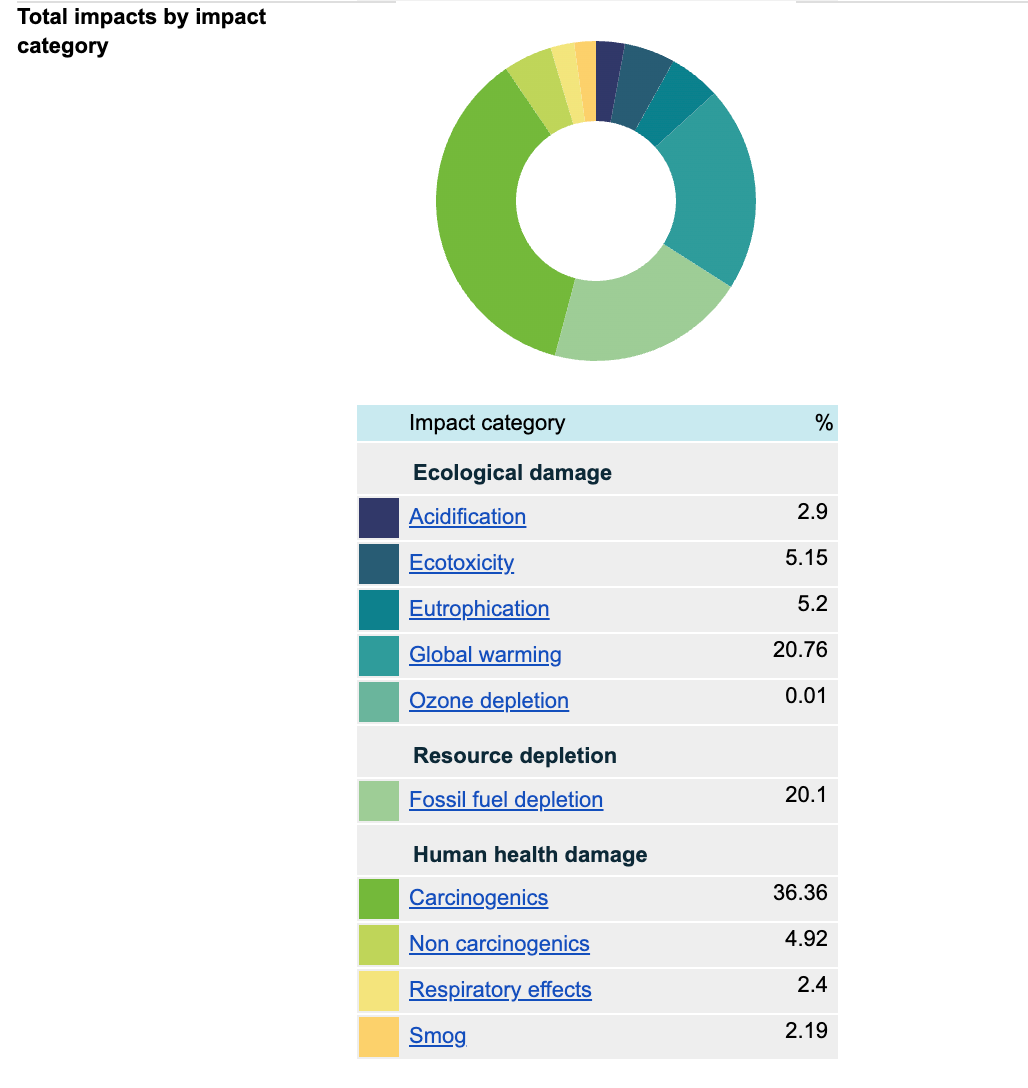

LCA Impact Assessment

The environmental impact assessment of the PET bottle was conducted using Sustainable Minds software. This analysis evaluated a range of impact categories, including acidification, ecotoxicity, eutrophication, global warming, ozone depletion, fossil fuel depletion, carcinogenic and non-carcinogenic effects, respiratory impacts, and smog formation.

Several of these categories directly relate to human health and ecosystem well-being. For instance, carcinogenic and non-carcinogenic impacts stem from the production of chemical compounds that can harm both people and the environment. The global warming category addresses climate change concerns by evaluating greenhouse gas emissions, such as carbon dioxide, methane, and nitrous oxide, among others. Ozone depletion is another crucial category, as it measures the potential damage to the ozone layer, which protects life on Earth from harmful ultraviolet radiation. Eutrophication, linked to phosphorous compound exposure, can lead to oxygen deprivation in plants and organisms, negatively impacting ecosystems.

Respiratory effects and smog are environmental impact categories related to the formation of tropospheric ozone and are a threat to health and quality of life. Acidification, caused by the release of chemicals like sulfur dioxide, can alter the pH balance of ecosystems, affecting their overall health. Ecotoxicity refers to substances that are poisonous to organisms in the ecosystem when emitted and fossil fuel depletion refers to the evaluation of the environmental effects associated with the extraction and consumption of non-renewable fossil resources.

Result and Discussions

The image below shows the total impact values of the single-use PET bottle in all the impact categories.

- Greatest Impact: The use of 100% virgin Polyethylene terephthalate (PET) is the most significant contributor to the overall environmental impact of the PET single-use plastic bottle.

- Impact Categories: The top impact categories were Carcinogenics (36.36%), Global warming (20.76%), and Fossil fuel depletion (20.1%).

- Life Cycle Stage: The manufacturing phase had the most significant environmental impact, consistent with findings from studies conducted in other countries.

Design for Sustainability

Today, we are using 1.6 earths (60% more resources than Earth can replenish per year).

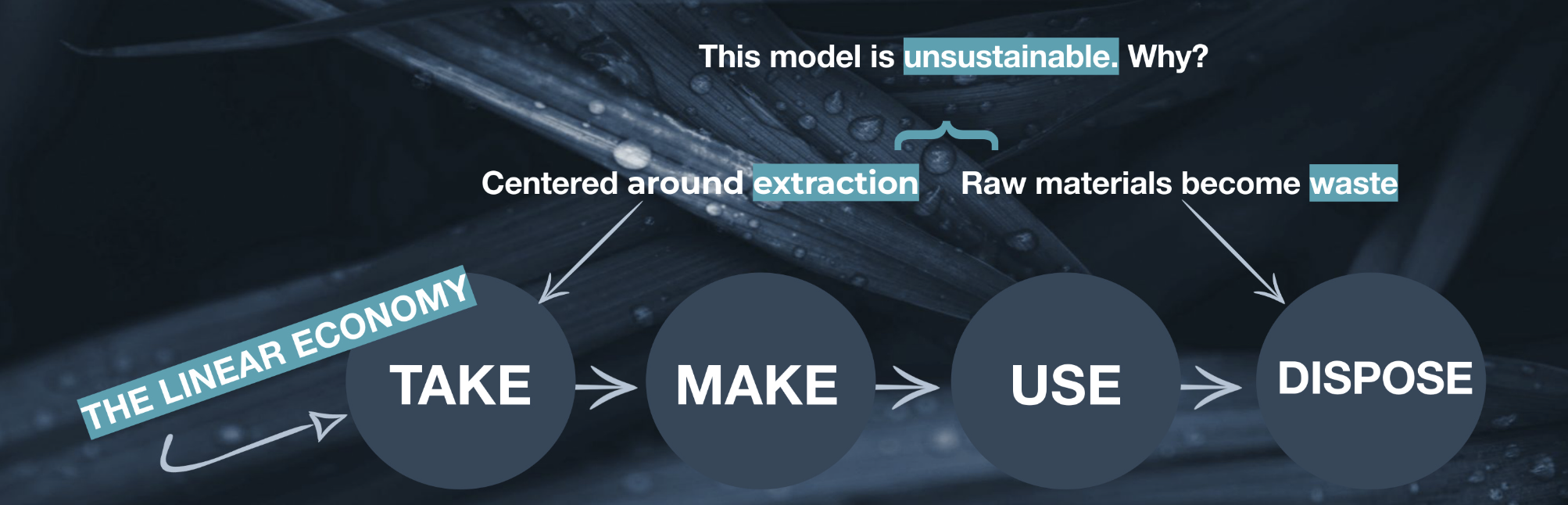

To create a sustainable world, we need to adopt a holistic approach to environmental impact, from production/manufacturing to disposal. This involves using green engineering principles and shifting from the linear "take-make-dispose” model to the circular economy to conserve resources, reduce waste, and design products with sustainability in mind.

Challenges

One of the key challenges I faced while conducting the LCA was obtaining reliable data, as there is a significant lack of comprehensive data available, particularly on the African continent. This limitation required working with estimates, which affected the precision of the analysis and underscored the need for better data collection and reporting in the region.

Conclusion and Recommendation

The significant impact of the manufacturing phase in the life cycle of the PET bottles confirms the need to design a much more lightweight single-use PET bottle and to reduce the mass of materials used in production. To address these challenges, innovations in sustainable design and manufacturing are focusing on reducing the thickness or mass of plastic bottles, as well as improving material selection and the use of recycled PET.

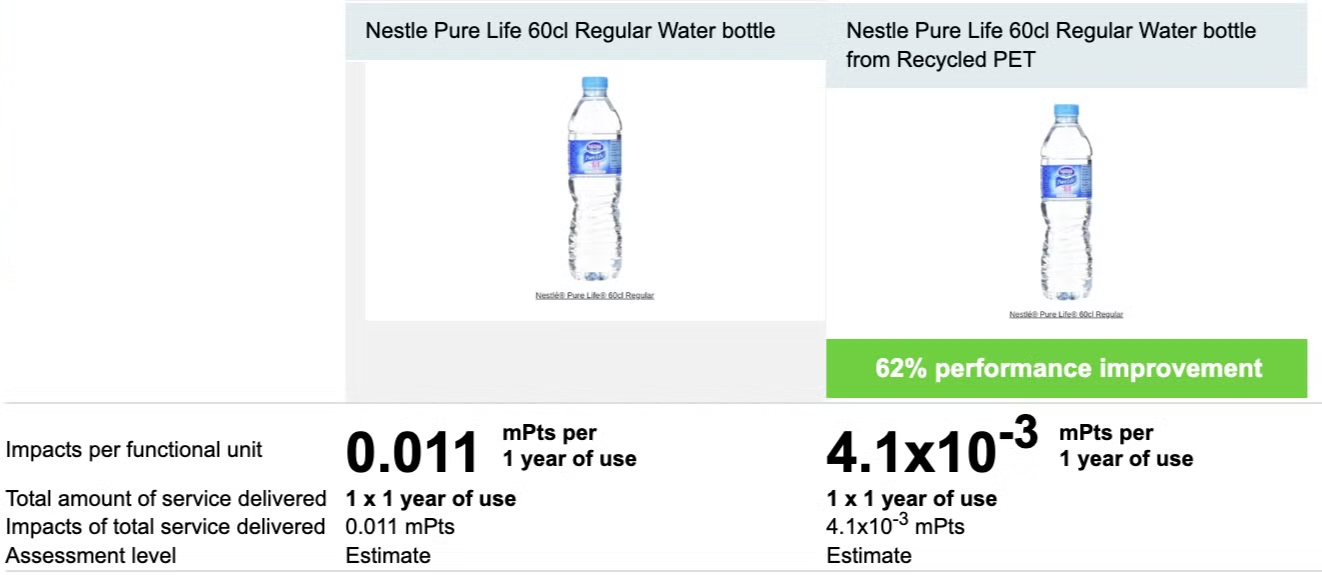

- Material Selection and Use of Recycled PET in Manufacturing Phase: PET bottle manufacturers should consider increasing the proportion of recycled PET in bottle production. By using rPET, the environmental impact associated with virgin PET production—such as fossil fuel depletion and global warming—can be significantly reduced.

To validate this, I modeled it in Sustainable Mind software using the following: a bottle cap made of 50% recycled and 50% virgin polypropylene (PP), and a bottle body made from recycled PET during the use phase. The results showed a 62% performance improvement, as illustrated in the image below.

- Packaging Design:

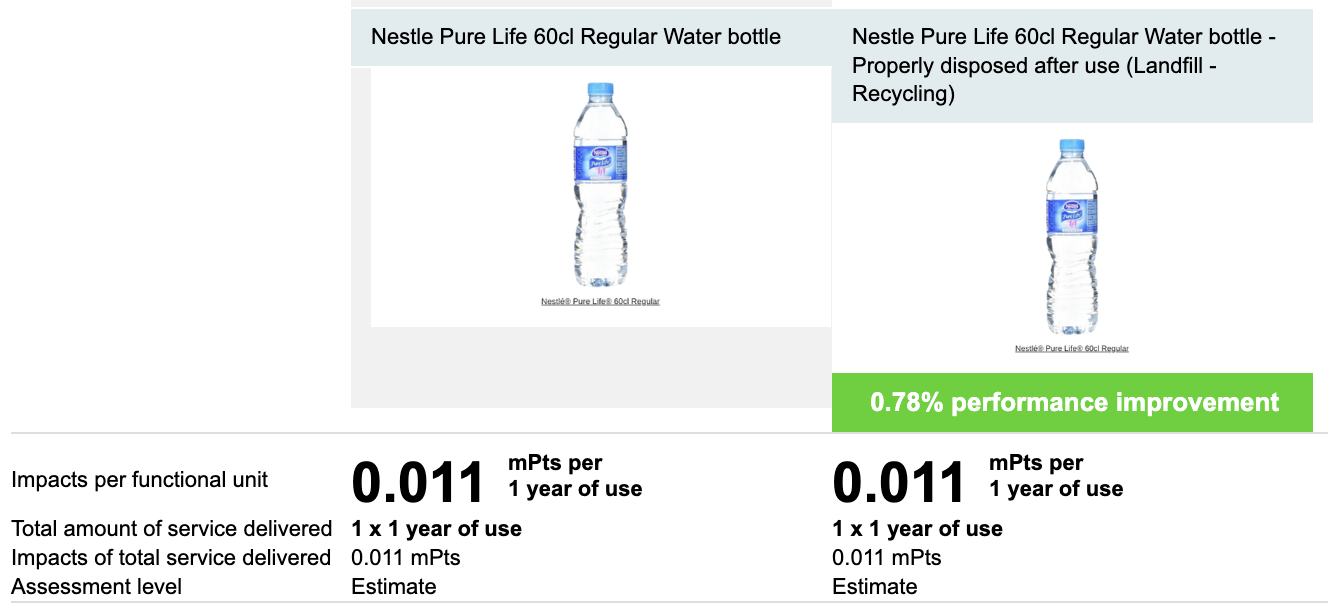

PET bottle manufacturers can optimize packaging design for greater efficiency by reducing material use without compromising functionality or durability. This could involve decreasing the thickness of the bottle or adopting a more efficient shape to minimize material usage. Minimizing secondary packaging, such as cartons or shrink wrap, can help reduce waste. Manufacturers could also explore offering larger, reusable, or refillable bottle options as sustainable alternatives to single-use bottles. - Proper Disposal methods for PET bottle (Landfill ⇒ Recycling):

A shift in consumer behavior and disposal methods for PET bottles from landfills to recycling can have a positive environmental impact. The LCA results below demonstrate a 0.78% performance improvement.

PET bottle manufacturers should educate consumers about proper plastic disposal and recycling by clearly labeling packaging and running campaigns that make the process easy to understand.

- Government and Private Sector Collaboration:

Addressing plastic waste in Nigeria requires a joint effort between government authorities and private waste management companies. With 230,000 tons of post-consumer PET waste generated annually from households and businesses, government and private sectors should collaborate to establish effective and decentralized waste management collection systems for PET bottles, containers, and other recyclable materials. - Standardising Extended Producer Responsibility (EPR) Policy:

EPR has been a key driver in advancing plastic recycling and has proven effective in supporting the broader goal of achieving circularity. It requires manufacturers to take full responsibility for products that have an impact on the environment. To strengthen plastic collection and recycling efforts, government agencies should incorporate EPR policies into all relevant plastic standards.

References

- Anastas, P.T., and Zimmerman, J.B. (2003). Design through the Twelve Principles of Green Engineering, Env. Sci. and Tech.

- Creating Shared Value Report, 2011

- Dr. Ganiyat Olusola Adebayo. (2024). An Update on Recycled Polyethylene Terephthalate (rPET) Standardisation in Nigeria.

- Market Assessment for Plastics Circularity in Nigeria

- Olatayo, Kunle & Mativenga, Paul. (2021). Life cycle assessment of single-use and reusable plastic bottles in the city of Johannesburg. South African Journal of Science. 117. 10.17159/sajs.2021/8908.